DSS Textiles

B - 217 Gopal Palace, Behind Hotel Maan Residency,

Near Jhansi Ki Rani BRTS Stop, Satellite Road, Ambawadi

Ahmedabad, Gujarat 380 009

India

ph: +91 9426413884

alt: +91 9033024241

sales

Rapier Loom for Technical Textiles

HERCULES Model of Panter, has the capabilities to weave Fabrics with warp beam tensions upto 3800 Kgs (10,000 N/Mtr) depending on the enduse and weaving requirements from 190 cm upto 5.5 meter width.

Wefts ranging from 10 denier to 43200 deniers have been handled with Positive Rapiers. Monofilaments of all types of fibers, Multifilament Yarns (with or without any twist) of all Fibers, Flat Tape Yarns (with or without Fibrillation), Carbon Spread Tow Yarns, Carbon Yarns, Kevlar, Aramid Yarns, Fiberglass Yarns and Rovings, (with or without Texturising, with or without any twist), Basalt, etc

Options to use any of the two Rapier systems (Namely Negative Rapier system or Positive Rapier System) at will as per needs of the weft yarn to be inserted in the fabric.

The Warp to the fabric path uses devices that are perfectly suited to ensure the machine's maximum flexibility and precision with both extremely heavy and dense fabrics or with rigid and low density yarns

The Weft Guiding elements are specially strengthned to avoid the wear effects of harsh yarns on the same, similarly the parts coming in contact with warp yarn and fabric are also specially reinforced to avoid long term abrasion. Guides with different profiles/shapes are available according to various needs.

The machines are built as per the unique demands of the Technical Textile being woven with strengthened body/Structure to withstand the weaving loads needed for the fabric proposed to be woven.

Some options like Full width temples , Reinforced Letoff and Takeup Motors, Main motors, Ultra Jumbo Backrest Rollers, back rest roller coatings, Takeup roller Covering, Fabric Guiding rollers with or without bearings, Expansion rollers near the temple, Thermal Cutters / Ultrasonic cutters / Chopper cutters for Fiberglass / Rotary Cutters for Carbon, Tapes are provided as per need of the client

Loom Size :145 / 160 / 190 / 210 / 230 / 240 / 260 / 280 / 300 / 320 / 340 / 360 / 380 / 440 / 460 / 550 cm

Weft Densities from 5 to 200 per cm (as standard) / 2 to 100 per cm (optional) / 0.5 to 50 per cm (optional)

Warp Feeding from Warp beams or from Creels are possible

Optional Electronic Panel from B&R with Touchscreen display and Regenerating Type of Servo Motors giving 25 to 33 % Power savings

Backrest Roller Assembly with Two Low Diameter Rolls of Very Low Weight/Mass

Fiberglass Scrim Weaving (with chopper cutter, Low Weft Density Weaving Kit)

Positive Rapier Transfer

Fiber Glass Roving Weaving

2 Ply of 2400 Tex in weft or equivalent to 43200 Denier in weft

AGRO TEXTILES

Shade Nets using Monofilament Warp yarn and Tape Yarns in Weft with variable densitied and widths to have different shading effecrts

- GEO TEXTILE REINFORCEMENT FOR ROADS upto 5.5 meter wide

.

.

Actual Customer Site Photographs (30 Loom Unit weaving Zero Twist Multifilament PES High Tenacity Yarns on our 5.5 Meter wide looms)

Geo Tube using PP Fibrillated Tape Yarns of 4600 Denier in Warp and 9200 Denier in weft

Anti Hail Nets with Full body LENO Weave upto 5.5 Meters wide

Insect Net / Screens upto 5.5 Meter wide

Basalt Weaving

Fiberglass Weaving

Kevlar Weaving

GEOTEXTILE Weaving on 5.5 meter wide Rapier Loom

Agro Textile Weaving using Monofilaments upto 5.5 Meters in width

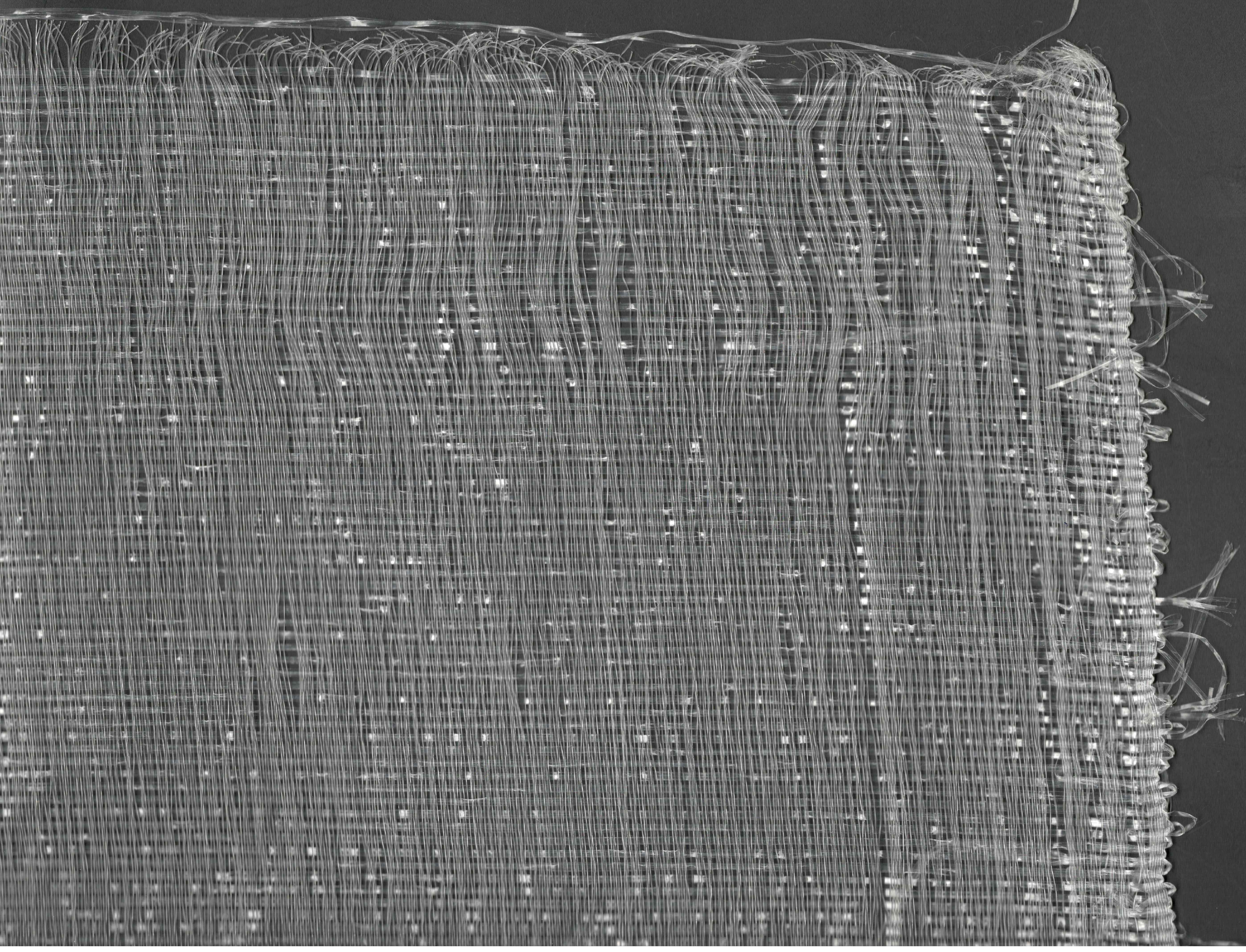

- Cotton Canvas Fabric Weaving

Fabrics with a cover Factor of 48 have been tested and woven till now.

This particular fabric was woven with 5 Ply of 8 Ne Cotton in Warp and Weft with a construction of 30 EPI and 21 PPI in plain weave with Full Width Temple

Copyright @2009 by Dwarkesh Sales & Services. All rights reserved. Web Hosting by Turbify

DSS Textiles

B - 217 Gopal Palace, Behind Hotel Maan Residency,

Near Jhansi Ki Rani BRTS Stop, Satellite Road, Ambawadi

Ahmedabad, Gujarat 380 009

India

ph: +91 9426413884

alt: +91 9033024241

sales